Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge.

Understanding customer’s requirement and ensuring to supply as per these requirements is realised with the help of quality assurance at Petrosadid one of the market leader, our product range include all types of flanges such as MS Flange (Mild Steel), Raised face flange, welding neck, Long weld neck, Slip on, threaded, blind, figure8, spectacle blind, spade and space, etc.

Forging Rolling

• Weight Measuring

• Cut Surface Check

• Marking

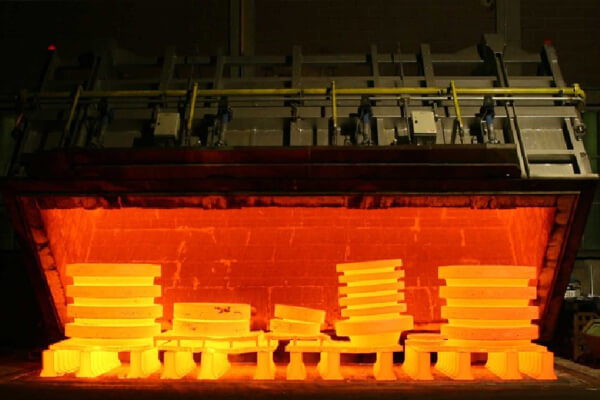

Flange Forging

• Material Grade Check

• Weight Measuring

• Temperature Control

Heat Treatment

• Normalizing

• Tempering, Q.T

• Solution Treatment

• Mechanical Test

Rust Prevention

• Preserve Check

• Marking on the flange

• Pickling ,Coating

Final Inspection

• Dimension size inspect

• Visual Test

• Nondestructive Test

Packing and Shipment

• Packing Spec. Check

• Packing Inspection

• Delivery